Stainless Steel 304 Woven Wire Mesh For Chemical Industry Plain Weave

Stainless Steel Wire Mesh Description

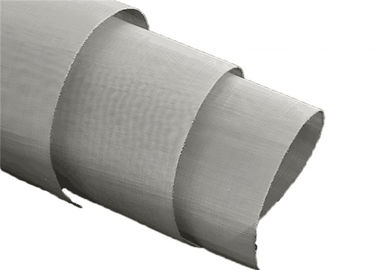

Woven wire mesh or woven wire cloth, is woven by machine. It is similar to the process of weaving clothing, but it is made of wire. The mesh can be woven in different weave styles. Its purpose is to produce solid and reliable products to adapt to various complex application environments.High precision technology makes the production cost of woven wire mesh higher, but it also has a very wide range of uses.

The main materials are 304 stainless steel wire mesh, 316 stainless steel wire mesh, 310 stainless steel wire mesh, 904L stainless steel wire mesh, 430 stainless steel wire mesh, and other stainless steel grade. The most popular ones are 304 stainless steel wire mesh and 316 stainless steel wire mesh, which can be used in most application environments and are not expensive. And some special materials are used to meet the high requirements of the use environment, such as Inconel wire mesh, Monel Wire Mesh, Titanium Wire Mesh, Pure Nickel Mesh, and Pure Silver Mesh, etc.

Stainless steel mesh is made of 304, 304L, 316, 316L, 310, 310s and other metal wire processing, smooth surface, no rust, corrosion resistance, non-toxic, health, environmental protection. Stainless steel mesh is mainly used in hospitals, pasta, meat barbecue, living basket, fruit basket series products, also used in some industries for filtering and screening.

|

Material

|

Stainless Steel Mesh For Filter Cloth

|

|

Material

|

SS 302,SS 304,SS 316 ,SS 304L, SS 3016L ect

|

|

Wire dia

|

0.017mm-5mm

|

|

Weave

Type

|

Plain weave can be woven from 1X1mesh to 635X635 mesh

|

|

Plain Dutch weave can be woven from 10X64mesh to 80X700 mesh

|

|

Twill Weave can be woven from 20X250mesh to 400X2800 mesh

|

Stainless Steel Wire Mesh Specification

| Stainless Steel Filter Mesh |

| Mesh |

Wire Dia.(Inch) |

Aperture(Micron) |

| 8*85 |

0.014*0.0126 |

250-255 |

| 12*64 |

0.024*0.0165 |

200-205 |

| 14*88 |

0.02*0.013 |

150-155 |

| 20*150 |

0.0098*0.007 |

100-105 |

| 24*100 |

0.015*0.01 |

80-85 |

| 30*150 |

0.009*0.007 |

65-70 |

| 40*200 |

0.007*0.0055 |

55-60 |

| 50*250 |

0.0055*0.0045 |

40-45 |

| 80*400 |

0.0049*0.0028 |

35-40 |

Stainless Steel Wire Mesh Feature

Plain weave can be woven up to 400 mesh.

Twill weave can be woven from 30-635mesh.

Common Width:0.914m,1.0m,1.22m,1.5m,Special requirement can be customized.

Characteristics of stainless Steel Wire Mesh:

Acid-resisting,alkali-resisting and anti-corrosion

High strength,good tension toughness and abrasion performance,durable in use.

resistance to high temperature oxidation

Highly polished, no need to do any surface treatment,with convenient and simple maintenance.

Stainless Steel Wire Mesh Application

Petroleum, petrochemical equipment, such as the reactor of petrochemical equipment.

Sulfuric acid storage and transportation equipment, such as heat exchangers;

Power plant flue gas desulfurization device, main parts are: absorption tower body, the flue, door plank, internal parts, spray system, etc;

Scrubber and fan in the organic acid processing system;

Water treatment plant, water heat exchanger, papermaking equipment, sulfuric acid, nitric acid equipment, acid, pharmaceutical industry and other chemical equipment, pressure vessel, food equipment;

Pharmaceutical factory: centrifuge, reactor, etc.

Stainless Steel Weave Style

Yuanhai Wire Mesh can provide many different weaves to meet different application needs. the weave styles mainly depend on the mesh and wire diameter specifications of the woven mesh. Below are the show of some common styles we weave here.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!