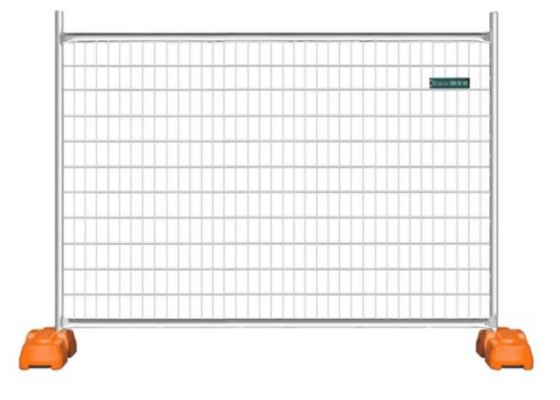

Anti Rust Australian Temporary Fence Heavy Duty Weatherproof Easy Store

Product Introduction:

This Australian Temporary Fence is innovatively designed to tackle harsh corrosive and variable weather conditions across Australia, fully adhering to AS 4687-2007 standards. It integrates four core strengths—superior anti-rust performance, heavy-duty durability, all-weather adaptability, and space-saving storage—by adopting high-grade anti-corrosion materials and a nested structural design. Specifically optimized for salt-fog coastal areas, high-humidity mining zones, and long-term outdoor construction sites, it maintains stable performance without rusting, deformation, or performance degradation even after years of exposure. Trusted by Australian port authorities, mining enterprises, and large construction firms, it balances reliable safety protection with hassle-free logistics and storage.

Key Specifications:

| Specification |

Details |

| Standard Size |

2.1m (height) × 2.4m (length) |

| Optional Size |

1.8m × 2.4m |

| Wire Diameter |

3.5-4.0mm |

| Mesh Size |

50×100mm / 60×150mm (anti-climb) |

| Frame Tube |

Φ32mm steel, 1.6mm+ wall thickness |

| Base |

HDPE blow-molded (26kg when filled with concrete/water) |

| Surface Treatment |

Hot-dipped galvanized |

Advantages:

Industry-Leading Anti-Rust Performance: Undergoes a 5-step anti-corrosion process (degreasing → pickling → rinsing → passivation → hot-dipped galvanization) and passes 500-hour neutral salt spray testing, ensuring no rust or corrosion even in coastal salt-fog environments for 8+ years.

Heavy-Duty Load-Bearing Capacity: 2.0mm thick frame tubes and high-strength carbon steel wires withstand direct impact from construction equipment (e.g., small forklifts) without deformation, making it suitable for high-traffic and heavy-construction areas.

All-Climate Adaptability: Engineered to resist extreme temperatures ranging from -10℃ (southern Australian winters) to 60℃ (inland summer heat), as well as prolonged heavy rain and intense UV radiation, with no fading or brittleness over time.

Effortless Storage & Transport: Panels feature a nested edge design that allows tight stacking—200 standard panels occupy only 15㎡ of storage space (30% less than conventional fences), and bases nest into each other to reduce shipping volume by 40%, cutting logistics costs significantly.

Applications:

Ideal for coastal port construction zones (resisting salt-fog corrosion), offshore wind farm staging areas, salt field isolation zones, high-humidity mining site partitioning (withstanding dust and moisture), heavy industrial construction sites (e.g., refineries), outdoor long-term storage yards (for machinery or materials), and large-scale agricultural events (e.g., livestock shows) requiring durable, low-maintenance isolation.

Production Process:

Precision Anti-Rust Preparation: After automated robotic welding, each fence undergoes thorough degreasing to remove oil residues, followed by pickling to eliminate surface oxides, and passivation to form a protective film—laying the foundation for uniform zinc adhesion during galvanization.

Reinforced Structural Fabrication: Frame corners are welded with 3mm-thick double-layer steel plates, and all welding seams are sealed with anti-corrosion paint to prevent moisture intrusion and rust formation from weld gaps.

Space-Saving Design Engineering: Panels are designed with overlapping, tapered edges to enable nested stacking, while bases are molded with internal grooves that allow each base to fit snugly over the next, minimizing storage and shipping footprint.

FAQ:

1.How does it perform in salt-fog coastal areas compared to regular temporary fences?

Unlike regular fences (which rust within 1-2 years in coastal areas), our dual anti-corrosion treatment (galvanization + passivation) and sealed welds ensure 8+ years of rust-free use, reducing replacement frequency by 75%.

2.What’s the maximum number of panels that can fit in a 40ft container?

A 40ft container can hold 450 standard panels (stacked nested) plus 450 filled bases (nested), maximizing container utilization and lowering per-unit shipping costs.

3.Can it withstand impact from construction vehicles?

Yes—lab tests show it can resist impact from a 1-ton forklift moving at 5km/h without permanent deformation, making it safer for busy construction sites.

4.How long does it take to install a large quantity for a project?

With quick-lock connectors (no tools required), a 3-person team can install 150m of fencing per hour—cutting installation time in half compared to bolted temporary fences.

5.Do you offer customizations for specific industry needs?

Yes—we provide customizations such as warning text printing (e.g., “Danger – Construction Zone”), reflective strip attachment (for night-time visibility in roadworks), and extra-thick frames (2.2mm wall thickness) for high-security mining sites, with a minimum order quantity of 150 panels.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!