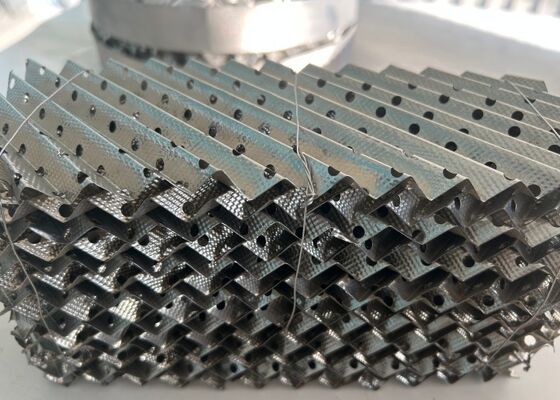

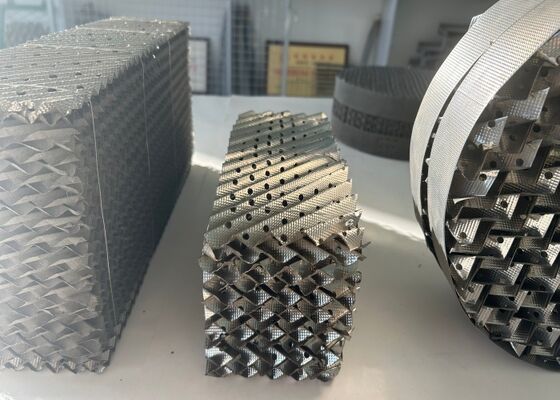

SS304/316 Metal Perforated Packing for Fine Chemical & Vacuum Distillation

Metal Structured Packing Packing Introduction

Yuanhai Metal Structured Packing is similar in construction to standard packing, except for a subtle modification in the geometry of the corrugation at the top and bottom of each packing layer. This relatively small change in geometry eliminates the abrupt change in flow direction of the liquid and vapor phases at the packing layer interface.

Conventional structured packing capacity is limited by flow interaction at the layer interface where the abrupt directional change limits the amount of counter-flowing liquid and vapor. As the liquid flow becomes restricted by the upward-flowing vapor, the liquid begins to build up at the layer interface which increases the pressure drop and may ultimately lead to flooding.

The geometry of Yuanhai structured packing relieves the liquid flow restriction. Because the premature build-up of liquid is eliminated, the low pressure drop characteristics of structured packing are better maintained throughout the efficient operating range of the packing. The benefits of Yuanhai structured packing are more significant for smaller corrugation crimp size, higher surface area packings. Depending on application and packing style, up to a 40% increase in capacity has been observed.

Metal Structured Packing Technical Specification

The specification is based on SS304 material:

| Item |

Surface Aream2/m³ |

Free Volume

% |

P

Pa/m |

Theo. plate

pc/plate |

F factor

m/s(kg/m³)0.5 |

| SB-125Y |

125 |

98 |

2x10-4 |

1-1.2 |

3 |

| SB-250Y |

250 |

97 |

2x10-4 |

2-2.5 |

2.6 |

| SB-350Y |

350 |

94 |

2x10-4 |

3.5-4 |

2 |

| SB-500Y |

500 |

92 |

3x10-4 |

4-4.5 |

1.8 |

| SB-125X |

125 |

98 |

1.4x10-4 |

0.8-0.9 |

3.5 |

| SB-250X |

250 |

97 |

1.8x10-4 |

1.6-2 |

3.5 |

| SB-350X |

350 |

94 |

1.3x10-4 |

2.3-2.8 |

2.2 |

| SB-500X |

500 |

92 |

1.8x10-4 |

2.8-3.2 |

2 |

Metal Structured Packing Advantages

| Packed columns |

Trayed columns |

| Lower pressure drop leads to significant power savings. (Greater than 5% reduction in power is possible.) |

Higher pressure drop, but shorter columns. |

| High turndown capability. (Down to 40% of design capacity is possible.) |

Limited turndown for efficient operation. (60-70% of design capacity is typical.) |

| Enables pure argon production by distillation, therefore eliminating need for a pure hydrogen source. |

Can be used for high-pressure distillation. |

Metal Structured Packing Advantages

High number of theoretical plates, large flux and low pressure drop;

Good performance with low working load, increased number of theoretical plates with the decrease of gas load, and there is almost no bottom limit of work load;

Large operation elasticity;

No obvious amplification effect;

Fulfilling the requirements of precision, large and high vacuum distillation units, providing favorable conditions for distillation separation system, heat sensitive material and high purity products.

Metal Structured Packing Application

Mass transfer of temperature sensitive chemical products

Proper lateral distribution of liquids and gases

Solvent recovery

Batch and continuous distillation

Low liquid loading systems

Providing highest theoretical stages per meter of packing height

Reducing liquid hold up

Economizing operating loads of vessels

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!