Engineering Filtration Perforated Wire Mesh Acoustic and Architectural

Product Overview

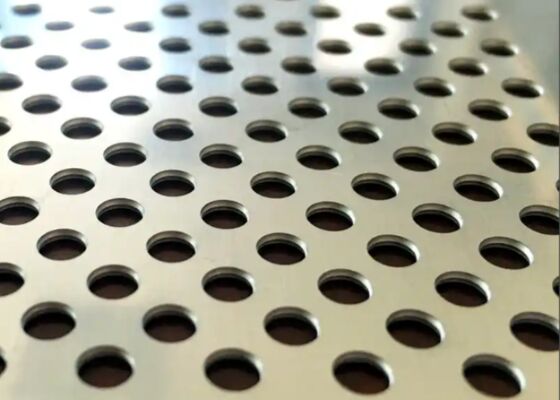

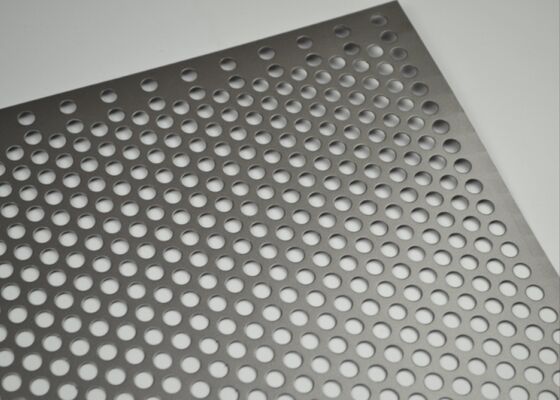

Perforated wire mesh is a highly controllable engineered product created by removing defined areas from sheet metal to form regular openings. Through selection of hole geometry, pitch, and plate thickness, designers can precisely tune airflow, pressure drop, filtration retention, acoustic diffusion, light transmission and visual opacity while preserving structural stiffness. This product line targets HVAC filtration frames, acoustic baffles, equipment guards, decorative façades and industrial screening. The following specification set and data examples are provided to assist engineering selection and procurement.

Manufacturing, Tolerances & Edge Conditions

Perforation is executed by mechanical punching or by CNC laser/waterjet cutting depending on batch size, hole complexity and plate thickness. Typical production controls include: tool clearance optimization to minimize burrs, progressive die staging for thick plates, and nesting strategies to maximize material yield. Key tolerance considerations: hole diameter tolerance (±0.05–0.2 mm typical), hole center-to-center tolerance (±0.1–0.5 mm), and plate flatness after perforation (specified in mm over 1 m). For panels that will be bent or welded, a minimum unperforated margin (commonly 10–20 mm) must be reserved; manufacturers can deliver pre-formed flanges or framed panels to simplify installation.

Technical Data Table

| Parameter |

Typical Range |

Remark |

| Materials |

SS 304 / 316, Carbon Steel, Al 3003 |

Select per corrosion & strength needs |

| Hole Diameter |

0.5 — 25 mm |

Smaller holes require thinner plates & finer tooling |

| Plate Thickness |

0.3 — 15 mm |

Thick plates may require special tooling or cutting |

| Open Area |

5% — 70% |

Function of hole geometry & pitch |

| Standard Sheet Sizes |

1000×2000 / 1220×2440 mm |

Custom sizes and nested cuts available |

| Tolerances |

Hole Ø: ±0.05–0.2 mm; Pitch: ±0.1–0.5 mm |

Depends on tooling and QC level |

| Surface Finishes |

Galvanized, Powder Coat, Anodized, Polished |

Environmental selection recommended |

Acoustic Behavior & Composite Assemblies

A single perforated panel provides modest diffusion and partial energy loss; substantial sound absorption is achieved when the perforated layer is combined with absorptive backing (mineral wool, foam, or fibrous mats) and cabinet depth. The absorber thickness, back cavity depth and perforation open area determine the peak absorption frequency and bandwidth. Typical design approach: use a perforated facing with 10%–25% open area over a 20–80 mm back cavity to target mid-frequency absorption in HVAC or enclosure applications.

Installation, Maintenance & Lifecycle Considerations

Installation-friendly options include pre-drilled mounting holes, factory-formed stiffening ribs, and captive frames. For external façades or coastal installations, specify 316 stainless steel or robust coating systems and provide for sacrificial maintenance cycles in the asset management plan. Routine maintenance: visual inspection, periodic cleaning (blowing, washing), and re-coating as needed. Lifecycle costing should include initial material premium versus long-term maintenance savings — coatings reduce short-term capex risk but may require periodic recoating in aggressive environments.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!