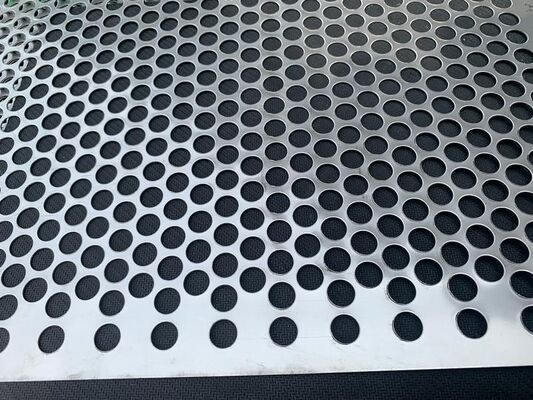

Heavy-Duty Perforated Wire Mesh for Filtration,Airflow,Structural Applications

Product Overview

Perforated wire mesh is engineered to provide both high strength and precision perforations for a variety of industrial and architectural applications. By removing specific areas of metal sheet to create regular openings, perforated wire mesh offers optimal balance between airflow, sound attenuation, filtration performance, and structural integrity. Available in multiple materials and hole shapes, it provides flexibility for customization based on different project needs, such as air ventilation, industrial filtration, protective enclosures, and architectural facades. The following details offer an in-depth look at its applications, advantages, and technical specifications.

Applications

Perforated wire mesh is utilized in various industries due to its versatility and unique properties. Some of the most common applications include:

1.Industrial Filtration: Perforated mesh serves as the first layer of filtration in air or liquid filtration systems, helping to trap larger particles before they reach finer mesh filters.

2.Air Ventilation: Used in HVAC systems, perforated mesh ensures optimal airflow while maintaining structural strength.

3.Acoustic Panels: By pairing perforated mesh with sound-absorbing materials, it helps control noise levels in factories, offices, and public spaces.

4.Protective Enclosures: The mesh is widely used for equipment safety enclosures, offering strong protection while allowing for cooling and ventilation.

5.Architectural Facades: For aesthetic and functional purposes, perforated mesh is used in building facades, providing sunshading and privacy while maintaining airflow.

Technical Data Table

| Parameter |

Value |

Notes |

| Material |

Stainless Steel 304, Galvanized Steel, Aluminum |

Choose based on environmental factors. |

| Hole Diameter |

1 mm – 20 mm |

Smaller holes for filtration; larger holes for ventilation. |

| Plate Thickness |

0.5 mm – 12 mm |

Thicker plates for structural reinforcement. |

| Open Area |

10% – 65% |

Optimized based on airflow or filtration needs. |

| Standard Sheet Size |

1000×2000 mm, 1220×2440 mm |

Custom sizes available upon request. |

| Surface Finish |

Powder Coated, Electroplated, Anodized |

Choose based on application and environment. |

Performance Advantages

Perforated wire mesh offers numerous advantages that make it the preferred choice in many industrial and architectural settings:

1.Strength and Durability: The mesh maintains structural integrity even in harsh environments, making it ideal for industrial use and outdoor applications.

2.High Customizability: With a wide range of hole shapes, sizes, and material options, perforated mesh can be tailored to meet specific project requirements.

3.Cost-Effective: It provides a lower cost solution compared to woven or welded wire mesh, with minimal material waste during production.

4.Efficient Filtration and Ventilation: The mesh offers efficient filtration for particulate matter, and its open structure facilitates superior airflow in ventilation applications.

5.Aesthetic Appeal: The mesh can be used in architectural designs for facades, sunshades, and decorative screens, offering both functionality and visual appeal.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!