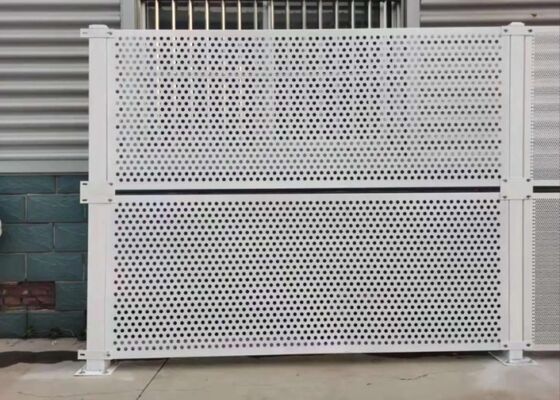

Perforated Wire Mesh for Customizable Solutions in Modern Infrastructure

Product Overview

Perforated wire mesh is no longer just a functional material—it has evolved into a highly versatile solution that meets both practical and aesthetic needs in the modern construction and industrial landscape. Through innovative engineering and precision manufacturing techniques, perforated wire mesh now offers customers the ability to create tailored solutions for a variety of applications. Whether it's designing complex facades for architectural masterpieces, filtering air or liquids in industrial systems, or reinforcing structural elements in high-stress environments, perforated wire mesh allows for both flexibility and durability.

In our design and manufacturing process, we prioritize customer input to create customized perforation patterns and material choices that fit specific project requirements. Whether the goal is maximizing strength, ensuring high filtration efficiency, or enhancing aesthetic appeal, perforated wire mesh provides an adaptable solution that aligns with modern infrastructure needs. Additionally, our materials are 100% recyclable, contributing to a circular economy and ensuring sustainability across industries.

Design Process and Customization

The design of perforated wire mesh begins with understanding the specific needs of each project. From the outset, our engineers work closely with customers to determine the ideal hole patterns, sizes, and materials. Advanced tools such as CAD (Computer-Aided Design) software are used to prototype and simulate the mesh layout, ensuring that the final product aligns perfectly with the desired functional and aesthetic goals.

Customization is a key feature of our service. Whether you're creating a visually striking building facade or a functional filtration system, the hole sizes and patterns can be adjusted to suit your needs. We provide an array of options for surface finishes, including powder coating, anodizing, and electrostatic coatings, which allow for additional protection against corrosion and enhance the longevity of the mesh in various environmental conditions.

Technical Data Table

| Parameter |

Typical Range |

Notes |

| Material |

Stainless Steel 316, Duplex Stainless Steel, Alloy Steel, Aluminum |

Suitable for use in corrosive, high-temperature, or high-stress environments. |

| Hole Size |

1 mm – 20 mm |

Custom sizes available for filtration or design purposes. |

| Plate Thickness |

1 mm – 8 mm |

Thicker plates provide higher structural strength. |

| Open Area |

10% – 75% |

Adjusted for airflow or filtration efficiency needs. |

| Surface Finish |

Powder Coating, Hot-Dip Galvanized, Electroplated, Anodized |

Choose based on exposure to the environment (high humidity, chemicals, etc.). |

| Standard Size |

1000×2000 mm, 1220×2440 mm, Custom |

Custom dimensions available for unique project needs. |

Conclusion

Perforated wire mesh represents an advanced solution for modern infrastructure needs, offering unparalleled versatility, strength, and durability. Whether you're looking to enhance structural integrity, optimize filtration systems, or create a visually striking architectural feature, perforated wire mesh offers the flexibility and customizability you need. Its eco-friendly design and sustainable manufacturing processes further enhance its appeal in today’s environmentally-conscious market.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!