Stainless Steel Wire Mesh Filter Cartridges For Fluid And Gas Separation Systems

Product Introduction

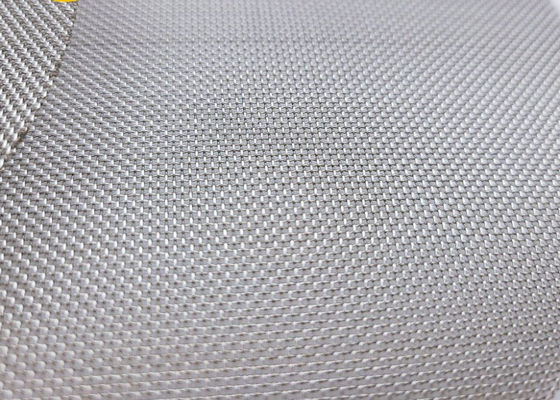

Stainless steel wire mesh filters are engineered metal filters produced by precise weaving or welding of stainless steel wires into controlled openings. They offer reusable, high-temperature resistant, chemically stable filtration media for liquid and gas streams. Available as flat sheets, pleated cartridges, discs or welded assemblies, these filters are widely used where polymer media fail — high temperature process streams, solvent filtration, steam, hot oil, and aggressive chemical environments.

Manufacturing & Integration Notes

Woven mesh element fabrication: cutting, edge-seaming, bonding to frames (welding, soldering or crimping). Pleating increases effective area ~3–6× depending on pleat geometry.

Welded or sintered assemblies for extreme duty: wire cloth is pleated and sintered or welded into rigid cartridges that withstand high differential pressures and backflushing.

Support structure: perforated core, spring-back spacers, and outer shrouds prevent collapse and allow backwash. Specify support if using fine meshes (<50 µm) at high flow rates.

Product Specification Sheet

| Item |

Typical Range |

Remarks |

| Mesh Count |

4 — 400 mesh |

coarse → superfine options |

| Nominal Opening |

~5000 µm → <5 µm (process dependent) |

exact opening depends on wire dia & weave |

| Wire Diameter |

0.05 mm — 4.0 mm |

affects strength & open area |

| Pressure Rating |

Vacuum — 100 bar (design) |

depends on element construction |

| Max Temp |

Up to 1000°C (SS 310) |

material dependent |

| Typical Form |

Cartridge, Pleated Pack, Disc, Panel |

specify housing compatibility |

| Clean Methods |

Backflush, Ultrasonic, Chemical CIP |

stainless allows aggressive CIP |

Working Principle

Stainless steel wire mesh filters separate solid particles from fluids or gases by physical interception. The woven or sintered mesh forms stable and repeatable openings, allowing media to pass through while particles larger than the designed aperture are retained on the surface or within the mesh layers. Compared with disposable fiber filter media, metal mesh elements maintain structural integrity under temperature fluctuation, pressure variation and repeated cleaning cycles.

Structural Design

According to application requirements, the wire mesh can be processed into single-layer woven elements or multi-layer sintered assemblies. Cylindrical and pleated designs significantly increase effective filtration area, helping to reduce pressure drop under continuous operation. Internal perforated tubes or expanded metal supports are added to prevent deformation when handling high flow rates or reverse cleaning.

Application Scope

These filters are commonly used in chemical processing, oil and gas pipelines, hydraulic systems, food and beverage processing lines, pharmaceutical production, powder recovery systems and environmental filtration equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!