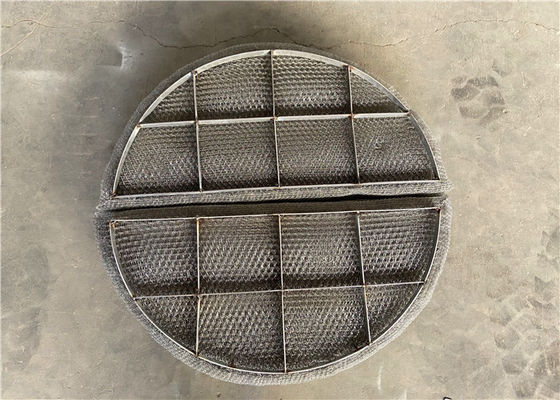

SS 304 Wire Mesh Demister Pad For Chemical Tower In Boiler Steam Drum

Wire Mesh Demister Pad Description

Mist Eliminators are designed to remove contaminants from process air emissions that evolve as mist droplets.

Demister pads in several materials like stainless steel 304, 316, polypropylene, ptfe and other features depending upon model and includeframes, metal grids etc.

These are used in pulp and paper, waste and water treatment, oil and gas, biofuel, geothermal power and other general industrial use.

Wire Mesh Demister Pad Specification

(1) standard type

|

Wire Diameter

dw(mm)

|

Width Tolerance

(mm)

|

Density

ρ(kg/m3)

|

Surface Area

α (m2/m3)

|

Void Fraction

ε

|

| Flat Wire |

Round Wire |

±20 |

150 |

Flat Wire |

Round Wire |

0.981 |

| 0.1*0.4 |

0.23 |

475 |

320 |

(2) High Penetration

|

Wire Diameter

dw(mm)

|

Width Tolerance

(mm)

|

Density

ρ(kg/m3)

|

Surface Area

α(m2/m3)

|

Void Fraction

ε

|

| Flat Wire |

Round Wire |

±20 |

98 |

Flat Wire |

Round Wire |

0.9875 |

| 0.1*0.4 |

0.23 |

313 |

217 |

(3) High Efficiency

|

Wire Diameter

dw(mm)

|

Width Tolerance

(mm)

|

Density

ρ(kg/m3)

|

Surface Area

α(m2/m3)

|

Void Fraction

ε

|

| Flat Wire |

Round Wire |

±20 |

182 |

Flat Wire |

Round Wire |

0.977 |

| 0.1*0.28 |

0.19 |

626 |

484 |

Feature of Wire Mesh Demister Pad

- They prevent emission of waste contaminants such as sulphur compounds, salt water, sand, hydrocarbons, etc. into protected interior spaces or out into the atmosphere.

- Designs are customised to the specifications of the fluids being processed. They remove 99.9% of liquid content in gas.

- When gas is passed through the demister, existing liquid particles in the gas hit the demister threads, build up due to molecular attraction, increase in size until they detach due to gravity and flow toward the drain.

- Wide range of work conditions in separation of liquid contaminants (including solids and associated gases in the flow of gas being processed: very fine sand, hydrocarbons, etc).

- High efficiency through various configurations and equipment with various stages.

- Flexible design conditions: Minimal pressure loss allowing for high gas speeds.

- Integrated purge or drainage systems.

The Demisting Process of Demister Pad

The operating principle behind the mist eliminator is simple. As the wet vapour stream rises through layers of contracting surfaces within the knitted and crimped wire matrix, entrained as they continuously impact each surface. The gas within the vapour stream continues to rise as the heavier liquids separate, attach and coalese into droplets within a mesh. as the droplets grow, so does their weight until they fall to the bottom of the vessel due to gravity. Liquid accumulations can then be drained out of the bottom as, the gas is routed through the top of the Vessel.

The Packaging of Demister Pad

1.Product are packed by Air Bubble Film. suitable for long distance transportation by sea,It can reduce abrasion when transport.

2.As customers' requirements

Delivery time

The product will be sent to you within 1-7 days after payment if in stock.

It will be take 7-15 workdays to produce if out of stock

Demister Pad Appilcations

* Elimination of toxic air pollutants

* Reduction of solvent losses in absorbers ,scrubbers and distillation equipment

* Optimization in kettles ,reboilers and crystallizers

* Elimination of entrainment

* Used in liquid -liquid systems

* Used as gaskets in cable, automobile and computer industry

* Gas-liquid ,solid-liquid separation

* Desalination plants

Demister Pad Show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!