SS Mass Transfer Metal Structured Column Packing 125Y Used In Petrochemical

Metal Structured Column Packing Introduction

1. Material: carbon steel, stainless steel, Ti, Aluminum foil, etc.

2. Model: from 125X(Y) to 1000X(Y)

3. Type: 15 types——PCC pak packing, wire gauze structured

packing, packing with perforated surface

4. Advantage: high cost performance.

Metal Structured Column Packing Technical Specification

The specification is based on SS304 material:

| Model |

void volume |

Piece thick |

Number per heaping |

Weave height |

Weave distance |

Gear-shape angle |

F-factor |

Theoretical hetp |

| (%) |

(mm) |

(kg/m3) |

(mm) |

(mm) |

φ |

φ |

(Piece/m) |

| 100Y |

87.5 |

2.5+/-0.5 |

460 |

30 |

50 |

80 |

3.5 |

1 |

| 125Y |

85 |

2.5+/-0.5 |

480 |

23 |

42 |

80 |

3 |

1-1.5 |

| 160Y |

84 |

2.2+/-0.5 |

500 |

17 |

30 |

80 |

2.8 |

1.5-2 |

| 250Y |

82 |

1.4+/-0.5 |

530 |

13 |

22 |

80 |

2.5 |

2-3 |

| 350Y |

80 |

1.2+/-0.5 |

580 |

9 |

15 |

80 |

2 |

3.5-4 |

| 450Y |

76 |

1+/-0.5 |

600 |

6 |

11 |

80 |

1.5-2 |

4-5 |

250(AX), Precision rectification for high productive capacity and less theoretical plate number.

500(BX), Vacuum rectification for thermosensitive system and hard separation system, especially suitable for rectification with pressure lower than 7Kpa.

700(CX), Separation of isotopic compound and isomeric compound.

Metal Structured Packing Material

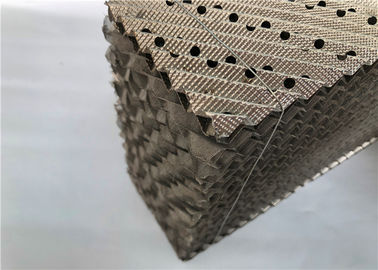

Structured packing is a range of materials that are specially designed for use in distillation and absorption columns, as well as chemical reactors. They usually consist of thin corrugated metal plates or gauzes, designed to force fluids on complicated paths throughout the column. The design is intended to ultimately produce a large surface area for contact between different phases.

Structured packing is made from a variety of materials including corrugated sheets of perforated embossed metal, plastic, or wire gauze. The resulting product is an open honeycomb with inclined flow channels producing a high surface area coupled with a low gas flow resistance. Enhancements are often chosen to maximize liquid spreading which are ideal for applications with low pressure and irrigation rates.

Metal Structured Column Packing Advantages

- 1. High number of theoretical plates, large flux and low pressure drop;

- 2. Good performance with low working load, increased number of theoretical plates with the decrease of gas load, and there is almost no bottom limit of work load;

- 3. Large operation elasticity;

- 4.No obvious amplification effect

Metal Structured Column Packing Application

Mass transfer of temperature sensitive chemical products

Proper lateral distribution of liquids and gases

Solvent recovery

Batch and continuous distillation

Low liquid loading systems

Providing highest theoretical stages per meter of packing height

Reducing liquid hold up

Economizing operating loads of vessels

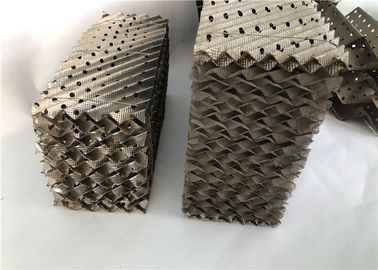

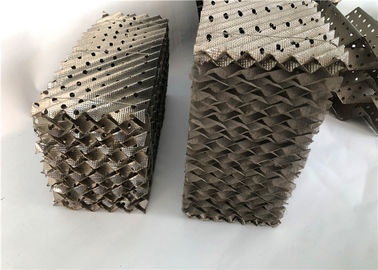

Metal Structured Column Packing Show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!