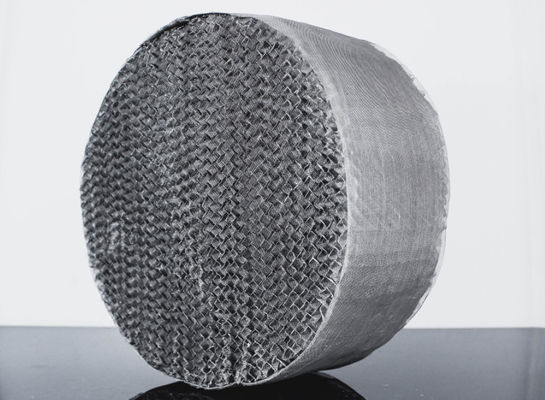

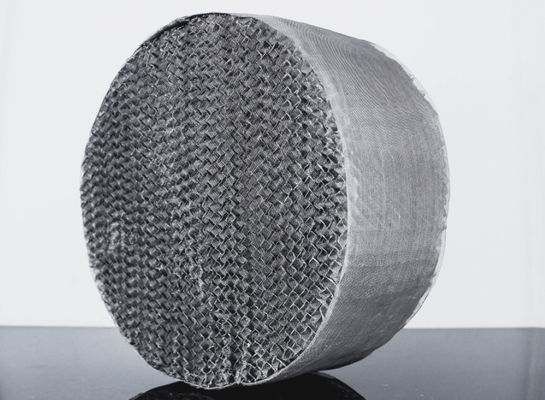

125X 350Y Metal Structured Packing Perforated Plate Corrugated Packing

Metal Structured Packing Introduction

Metal Structured Packing is made of perforated plate with channel corrugation on surface, and remains structure feature of metal wire gauze packing.

Metal Structure tower packing strengthens uniform liquid distribution and surface wetting ability, which increases mass transfer efficiency.Metal structured packing has feature of specific surface large, void ratio high and weight light; Gas path obliquity small and regular, pressure drop low; Radial diffusion good, gas liquid contact sufficient.

Metal Structured Packing Technical Specification

The specification is based on SS304 material:

| Item |

Surface Aream2/m³ |

Free Volume

% |

P

Pa/m |

Theo. plate

pc/plate |

F factor

m/s(kg/m³)0.5 |

| SB-125Y |

125 |

98 |

2x10-4 |

1-1.2 |

3 |

| SB-250Y |

250 |

97 |

2x10-4 |

2-2.5 |

2.6 |

| SB-350Y |

350 |

94 |

2x10-4 |

3.5-4 |

2 |

| SB-500Y |

500 |

92 |

3x10-4 |

4-4.5 |

1.8 |

| SB-125X |

125 |

98 |

1.4x10-4 |

0.8-0.9 |

3.5 |

| SB-250X |

250 |

97 |

1.8x10-4 |

1.6-2 |

3.5 |

| SB-350X |

350 |

94 |

1.3x10-4 |

2.3-2.8 |

2.2 |

| SB-500X |

500 |

92 |

1.8x10-4 |

2.8-3.2 |

2 |

Metal Structured Packing Advantages

1. The pressure drop of the structured packing is significant

2. High efficiency of structured packing separation

3. The regular packing has a small liquid holding capacity

4. Regular packing gap is large

5. The device startup time is greatly shortened

6. The oxygen content in the argon fraction is about 90%.

Metal Structured Packing Application

Metal plate corrugated packing with high flux, low resistance, high efficiency, the advantages of anti-blocking ability. In distillation, absorption, and extraction unit operation widely used, According to filler type, the minimum diameter of 80- 200mm, maximum diameter reached 13m, density of the liquid spray from 0.2-220m /m .hr, the pressure range from vacuum to high pressure. Is used in chemical, fertilizer, oil refining, petrochemical, natural gas and other industrial versatile and efficient structured packing. Theoretical plate number of the packing high flux, low pressure drop, low load, performance, operating flexibility, amplifying effect is not obvious.

Used in fine chemicals, spices, isomer separation, difficult to isolate system, heat-sensitive substances and products of high purity distillation, separation has significant results.

FAQ

Q: Are you a manufacturer?

A: Yes,we have specialized in this field for about 10 years experience.

Q: Could you provide sample?

A: Yes,we can provide sample together with our catalogue. But the courier charge will on your side. We'll send back the courier charge if you make an order.

Q: What information should I provide,if I want a lowest quotation?

A: The specification of wire mesh.such as material,mesh number, wire diameter,hole size,width,quantity,finishing.

Q: How is your delivery time?

A: We always prepare enough stock material for your urgent requirement. the delivery time is 7days for all the stock material.

We'll check with our production department for the non-stock items to offer you the exact delivery time and producing schedule.

Q: How do you ship the finished wire mesh?

A:Usually by sea.

Q: What is the payment?

A:We usually use the T/T,L/C,D/P,Western Union.

Our Company

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!