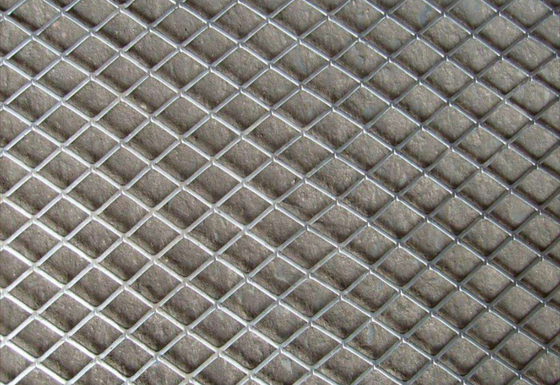

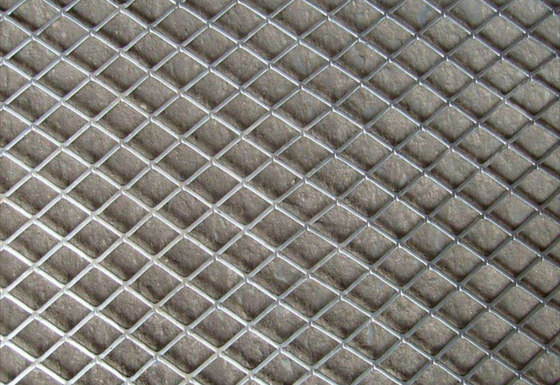

High Strength Versatile for Security Filtration Applications Expanded Wire Mesh

Product Overview

The Expanded Metal Wire Mesh is a versatile and high-strength mesh material created by slitting and stretching a metal sheet. This process results in a series of diamond-shaped openings that provide strength, flexibility, and excellent ventilation. Made from materials such as low-carbon steel, stainless steel, or aluminum alloy, expanded metal mesh is highly durable and corrosion-resistant. It is commonly used in industrial, security, and filtration applications where strength, durability, and airflow are key considerations.

Construction & Features

The expanded metal mesh is manufactured through a process that slits and stretches a solid sheet of metal, creating a continuous, durable mesh with diamond-shaped holes. The result is a mesh that is strong, lightweight, and resistant to deformation. This structure allows for high airflow, making it ideal for applications such as security fencing, walkways, drainage covers, and filtration systems.

Applications & Benefits

This type of mesh is widely used in a variety of industries, including construction, mining, oil, and gas, as well as for security and filtration applications. Its high strength and ability to resist deformation make it an excellent choice for use as a safety barrier, walkways, and in industrial filtration systems. The mesh is also commonly used for air vents, grilles, and drainage channels due to its excellent ventilation properties.

Corrosion Resistance & Durability

The expanded metal mesh is designed to withstand exposure to harsh environments. The material's resistance to corrosion is enhanced with coatings such as hot-dip galvanizing, powder coating, or the use of stainless steel. This ensures that the mesh maintains its structural integrity and appearance even in outdoor environments or areas with high moisture levels.

Installation & Maintenance

The expanded metal mesh is easy to install due to its rigid structure. It can be fastened to frames or supports using standard bolts or clamps. The mesh can also be customized to fit specific project requirements in terms of size, mesh design, and surface finish. Minimal maintenance is required, as the mesh's open design allows for easy cleaning and removal of debris, ensuring it continues to perform efficiently.

Technical Data

| Attribute |

Typical Value |

| Material |

Low-carbon steel / Stainless steel / Aluminum alloy |

| Mesh Aperture |

10×10 mm / 20×20 mm / 30×30 mm (customizable) |

| Thickness |

1.0–6.0 mm |

| Dimensions |

1.0×2.0 m (customizable) |

| Load-Bearing Capacity |

High load-bearing capacity, suitable for heavy-duty applications |

| Surface Finish |

Hot-dip galvanized / Powder-coated / Stainless steel |

| Ventilation Efficiency |

Excellent airflow and permeability |

| Packing |

Palletized flat packing + moisture-proof wrap |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!