Heavy‑Duty Expanded Metal Mesh Panels for Structural Protective Engineering

Manufacturing Process

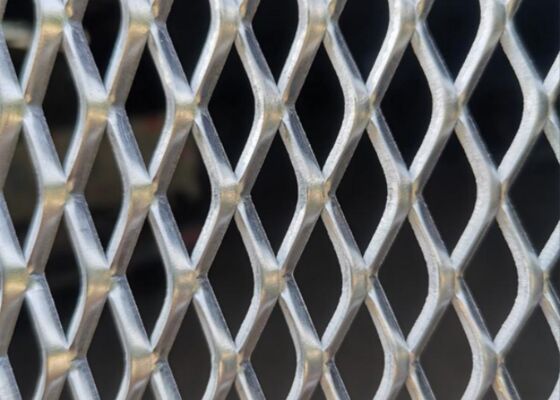

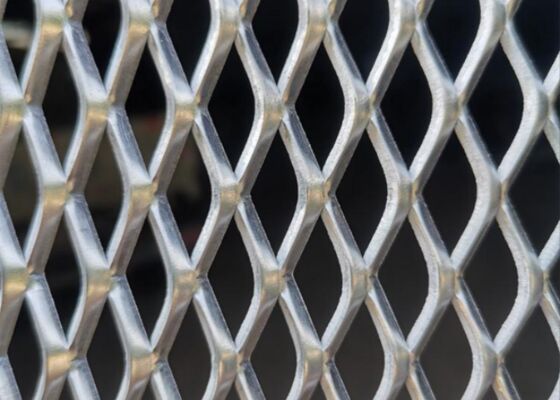

Expanded metal mesh is produced by a simultaneous slitting and stretching process that transforms a single piece of metal sheet into a network of interconnected strands and openings. Unlike welded or woven wire meshes, the expanded mesh has no joints, which gives it continuous grain integrity and improved mechanical properties. Depending on the design, expanded mesh may be manufactured with raised ribs for structural rigidity or flattened profiles for smoother surface requirements.

Materials selected for expanded metal mesh are determined based on structural requirements, environmental conditions, and corrosion resistance needs. Carbon steel is often used in heavy structural implementations, aluminum is chosen for lighter load and corrosion environments, and stainless variants are applied where high chemical resistance is critical.

Mechanical Performance

Performance characteristics of expanded metal mesh are evaluated through a series of standard mechanical tests such as tensile strength, yield stress, elongation, and fatigue resistance. Expanded products demonstrate superior load distribution and energy absorption capabilities compared to perforated sheets of equivalent thickness.

Quality control procedures for each batch include dimensional verification with calibrated gauges, visual inspection for surface uniformity, and checking open area ratios to ensure compliance with design specifications. These steps are critical in applications requiring precision tolerance such as filtration systems and precision shielding.

Specialty Applications

Beyond general architectural and industrial usages, expanded metal mesh serves niche roles in several specialized markets:

1. Acoustic & Vibration Control Sections

When laminated with sound‑absorbent materials or layered in staggered constructions, expanded mesh contributes to sound attenuation in industrial enclosures or equipment rooms. Its open pattern facilitates air flow while breaking sound waves.

2. Filtration & Separation in Chemical Plants

Fine expanded meshes with precise opening sizes are utilized in liquid and gas filtration stages. Mesh dimension tolerances are controlled to meet filtration gradients without compromising fluid throughput.

3. Reinforcement in Composite Fabrication

Expanded metal serves as an embedded reinforcement within polymer or concrete composites where multidirectional strength is required. The mesh’s interconnected grid provides mechanical interlock with matrix materials.

Environmental Resistance & Surface Engineering

Expanded metal mesh intended for corrosive, marine, or high‑humidity environments is frequently treated with advanced surface engineering techniques such as powder coating, anodizing (for aluminum), or zinc flake coatings. These treatments enhance resistance to oxidation, UV exposure, and chemical attack.

Post‑treatment adhesion and coating thickness uniformity are verified using cross‑cut adhesion testing per ISO standards and coating thickness gauges to ensure long‑term reliability in harsh service conditions.

If you need more detailed technical support or a quote, feel free to contact us anytime.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!