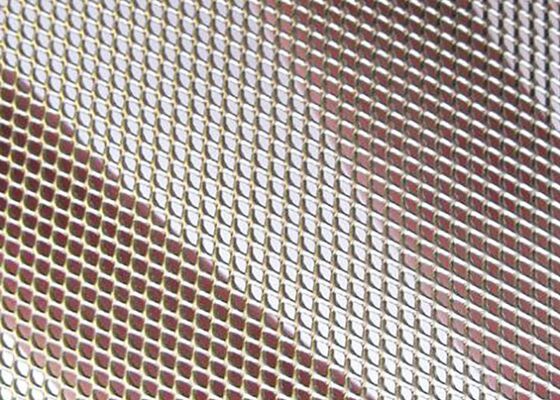

Titanium TA1 Expanded Mesh For Hydrogen Fuel Cell Anode Mesh 3*5mm

Description of Expanded Metal Mesh

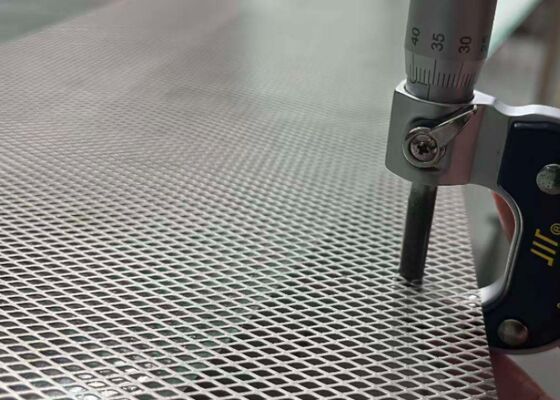

The primary distinction in expanded metal lies in its post-production processing. Raised mesh (Standard) is the direct result of the slitting and stretching process, where the strands and bonds are set at a sharp angle to the plane of the sheet. This creates a 3D surface with exceptional rigidity and natural slip resistance, making it the go-to choice for industrial walkways and safety grates.

In contrast, flattened mesh is created by passing the raised mesh through a cold-rolling mill. This reduces the thickness of the strands and levels them into a single horizontal plane. The result is a smooth, safe-to-touch surface that is roughly 5% lighter and ideal for architectural partitions, furniture, and filtration screens where a flush finish is required.

Specification of Expanded Metal Mesh

|

Material

|

Titanium, nickel, Alloy, Copper, Brass, Monel, and other alloy metal....

|

|

Thickness

|

0.05mm, 0.1mm 0.3mm 0.5mm, 0.8mm, 1.0mm 2mm, to 5mm

|

|

Type

|

Flattened Expanded Mesh Type, Standard Expanded Mesh Type

|

|

Hole Size

|

1*2mm 0.5*1mm 2*4mm 3*5mm 4*8mm 5*10mm....

|

|

Treatment

|

Coating treatment can be provided as per your request.

|

Features of Expanded Metal Mesh

1. Extreme Corrosion Resistance

Titanium forms a stable protective oxide layer, providing near-permanent durability in marine environments, strong acids (like nitric acid), and chlorides—far outperforming stainless steel.

2. High Strength-to-Weight Ratio

Titanium offers strength comparable to steel but is approximately 45% lighter. The expansion process creates a one-piece structure without welds or joints, ensuring high integrity with significantly reduced weight.

3. Excellent Electrochemical Performance

It is an ideal substrate for electrolysis, water treatment, and hydrogen energy. It is widely used as a base for MMO (Mixed Metal Oxide) coated anodes in fuel cells and desalination systems.

4. Superior Stability & Biocompatibility

-

High-Temperature Resistance: Maintains structural stability in environments up to 600°C.

-

Biocompatible: Non-toxic and non-magnetic, making it suitable for medical implants and precision filtration.

Applications of of Expanded Metal Mesh

Hydrogen Production: The titanium mesh is commonly used in PEM electrolyzers to facilitate the electrolysis of water, producing high-purity hydrogen. The mesh acts as an electrode support, offering superior surface area for efficient ion exchange.

Energy Storage Systems: It is used in energy storage solutions where electrolysis is employed to store energy in the form of hydrogen, contributing to green energy initiatives and renewable power generation.

Electrochemical Synthesis: Titanium expanded metal mesh plays a critical role in the development of various electrochemical processes, such as metal plating and chlorine production, due to its excellent resistance to aggressive chemicals.

Marine Applications: Its corrosion-resistant properties make it suitable for marine environments, where it can be used in electrolytic cells for desalination and water treatment systems.

Fuel Cells: The mesh is used in fuel cells as a conductive material, enabling efficient hydrogen generation for fuel cell applications.

With its durability and versatility, PEM Electrolytic Cell Titanium Expanded Metal Mesh ensures enhanced operational efficiency and longevity in demanding environments, making it a preferred choice for industries focused on sustainable energy and advanced electro chemical technology.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!