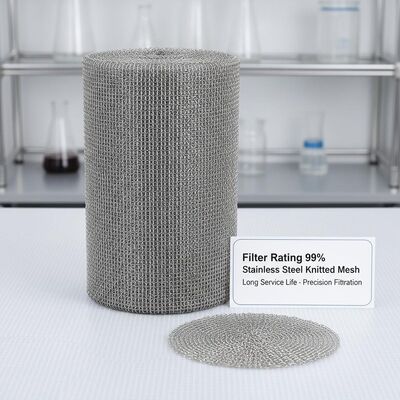

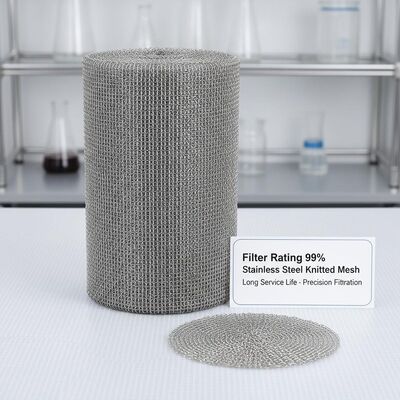

Product Description:

The wire mesh demister pad, also referred to as a wire mesh defogger or bubble trap, is a highly efficient device designed for gas-liquid separation. This equipment plays a crucial role in various industrial sectors due to its effectiveness and reliability.

It is extensively utilized in industries such as chemical processing, petroleum refining, sulfuric acid production, pharmaceuticals, light manufacturing, metallurgy, machinery, construction, and aviation. Additionally, it finds significant application in maritime transportation and environmental protection fields.

Moreover, wire mesh demister pads are incorporated in production equipment for processes involving ethylene, synthetic ammonia, and chemical fibers—often imported from abroad—to enhance gas-liquid separation performance. The primary function of this device is to remove droplets with diameters ranging from 3 to 5 micrometers, ensuring efficient separation and improved operational outcomes.

Applications:

This product finds extensive applications across various industries including petroleum, chemical, metallurgy, machinery, pharmaceuticals, and the automobile sector. Its versatility makes it an essential component in many industrial processes.

In addition, it plays a significant role in environmental protection efforts. The device is commonly used for distillation, absorption, evaporation, and filtration tasks. These functions help in removing entrainment and foam that may be present in gases and liquids.

By efficiently eliminating impurities mixed within gases and liquids, it ensures smoother operation and enhanced product quality in many industrial operations.

Support and Services:

Our Wire Mesh Demister Pads are designed to efficiently remove liquid droplets from gas streams, ensuring optimal process performance and equipment protection. For technical support, our team provides detailed guidance on pad selection, installation, and maintenance to maximize demisting efficiency and extend product lifespan.

We offer comprehensive services including custom sizing, material selection assistance, and troubleshooting support tailored to your specific application requirements. Our experts can help you evaluate operating conditions to recommend the most suitable Wire Mesh Demister Pad configuration.

Installation support includes detailed instructions and best practices to ensure proper placement and secure fitting within your equipment. Maintenance services cover inspection protocols and cleaning procedures to maintain high separation efficiency and prevent clogging or corrosion.

In addition, we provide performance testing and analysis to verify pad effectiveness and identify any potential issues early. Our commitment is to deliver reliable, high-quality support that helps you achieve optimal separation performance and operational uptime.

FAQ:

Q1: What is the brand and model number of the Wire Mesh Demister Pad?

A1: The Wire Mesh Demister Pad is manufactured by Yuanhai, and the model number is YH-06.

Q2: Where is the Wire Mesh Demister Pad produced?

A2: This product is made in Hebei, China.

Q3: What certifications does the Wire Mesh Demister Pad have?

A3: The Wire Mesh Demister Pad is certified with ISO9001:2015.

Q4: What is the minimum order quantity and can the price be negotiated?

A4: The minimum order quantity is 5 pieces, and the price is negotiable based on order quantity and specifications.

Q5: How is the Wire Mesh Demister Pad packaged and what is the delivery time?

A5: The product is packaged in a wooden box, and the delivery time is typically 10 days.

Q6: What are the payment terms and supply ability for this product?

A6: Payment terms accepted are T/T and L/C. The supply ability is 10,000 square meters every 7 days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!